Our Capabilities

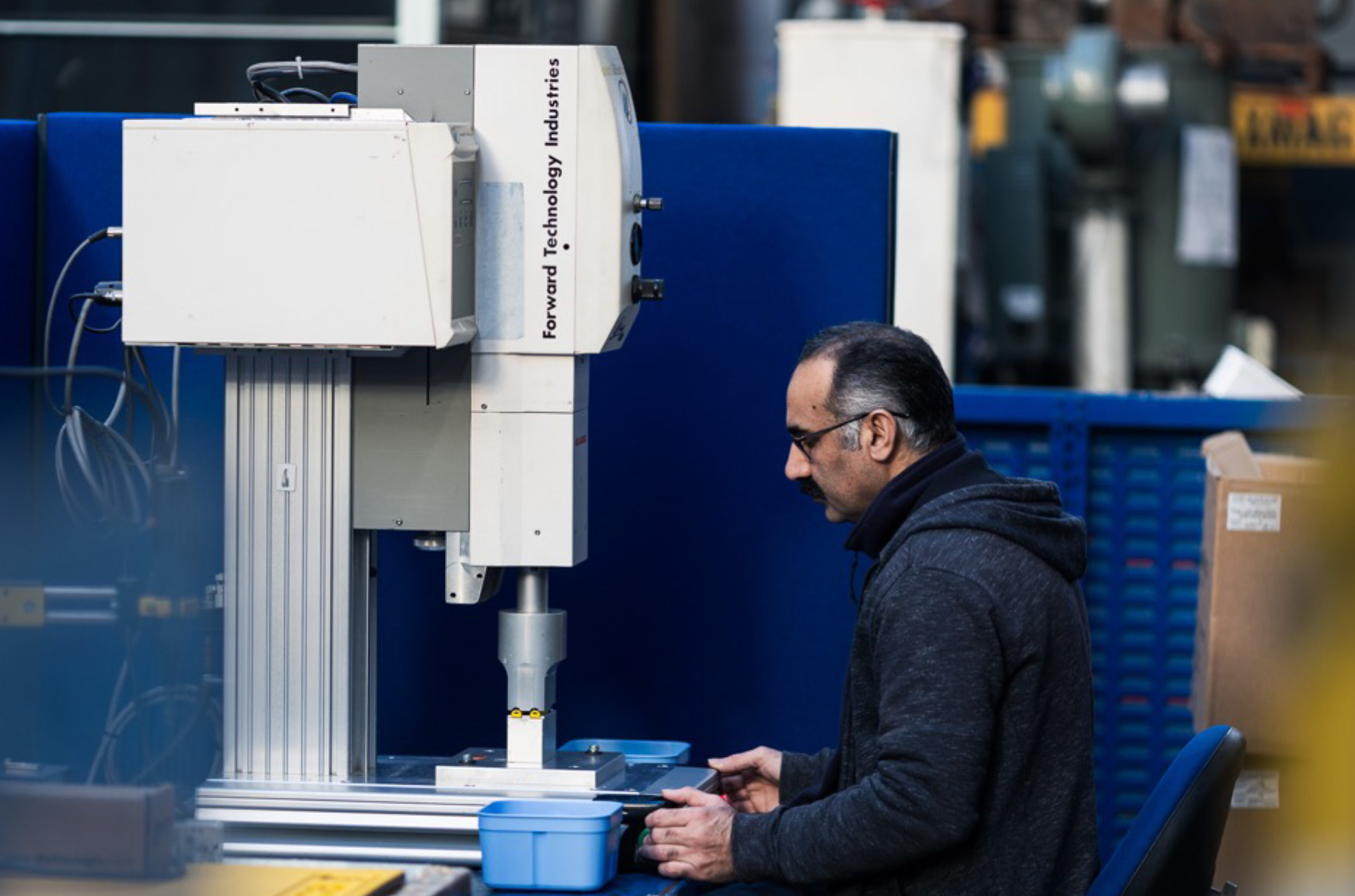

Ultrasonic welding

Injection Moulding

Pad Printing

Toolmaking

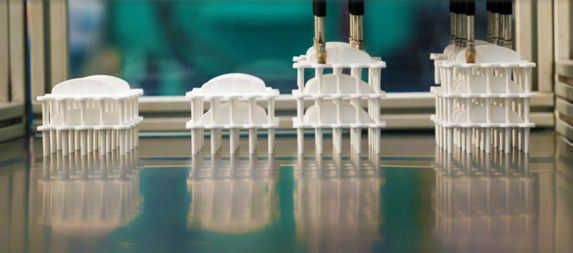

Cleanroom

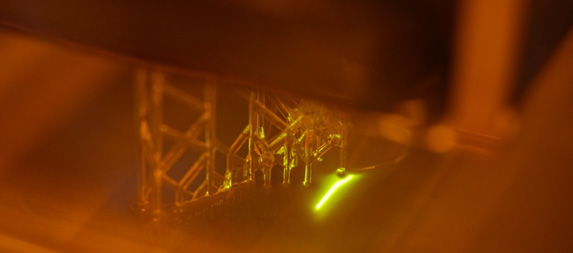

3d Print Tooling

Not just injection moulders and toolmakers

Established in 1975, Andel Plastics offer a full service from component concept feasibility advice, mouldflow analysis, prototype tooling, through to full production tooling. This transfers to our injection moulding facility for component manufacture. We then offer a full range of assembly services, post machining, ultrasonic welding and a printing service. All these services under the same roof with our expert team.

Latest from the blog

Testimonials

ANDEL Plastics offer expertise, understanding and innovative outcomes to a whole suite of areas we work in.

Being so much more than a me-too manufacturer, and having the ability to work in a collaborative manner enables us to grow the relationship long term and constantly plan for future areas of improvement.

Moflash has worked with Andel Plastics for over 26 years & in that time the quality & service has been second to none. Any successful commercial enterprise between two companies relies on the trust that both parties bring to that Relationship & we have always felt that Andel Plastics have gone out of their way to maintain it. I would highly recommend Them to any new customers who are looking for either injection moulding or tool making capabilities in the UK.

Great company to work with. Super helpful with refining designs and suggesting improvements and even creating new ideas when I was stuck, wouldn’t hesitate to recommend.